Sustainable and effective treatment of your water system.

Overview

Biofilm Challenges

Water circuits provide the ideal conditions for biofilm formation, scaling deposits and corrosion. Biofilms may endanger health and safety, damage materials, reduce heat transfer and disrupt flow processes,decreasing the energy efficiency of industrial systems.

Conventional biofilm treatments are usually cost-intensive, time-consuming and aggressive to materials and the environment. For the prevention of these hazards Veolia Water Technologies now offers a new option: solid-state catalysts.

Biosurfactants against biofims

Veolia Water Technologies offers modern high-performance catalysts for natural disinfection of the water circuits. This innovative and proven technology is able to eliminate the biology in water transfer systems extremely effectively and environmentally soundly. With the aid of catalytically generated biosurfactants, biofilms will be detached from the surfaces of the water circuit without compromising product quality, people or the environment.

With BerkeLYT technology, Veolia Water Technologies offers a cost efficient yet non-harmful alternative: the sustainable elimination of biofilms by catalytically generated biosurfactants.

Benefits

Main benefits of the BerkeLYT technology include:

- High effectiveness in the sustainable removal and prevention of biofilms

- Health protection due to the reliable prevention of legionella

- Increase of energy efficiency

- Corrosion prevention

- Environmentally friendly by eliminating the use of non-oxidizing biocides

- Non-harmful by-products

- Verifiable lower energy consumption and carbon footprint of BerkeLYT technology compared with alternative systems

- Reduction of operating costs

- Low maintainability and high reliability in long-term operation

Applications

BerkeLYT is a versatile technology and can be used in multiple applications:

- Open and closed cooling circuits/cooling towers

- Ventilation and air-conditioning technology/air washer

- Swimming pools

- Wells

- Fountains

- Process water (RO systems)

- Production processes

- Sprinkler systems

References

The technology proved itself in power stations and chemical production plants in the treatment of cooling water, to protect reverse osmosis systems and in air-conditioning units.

- Public buildings, e.g. shopping centers, hospitals, hotels, office buildings

- Automotive

- Power plants

- Food processing industry

- Swimming pools

- Other industrial companies

- Agriculture

Applications

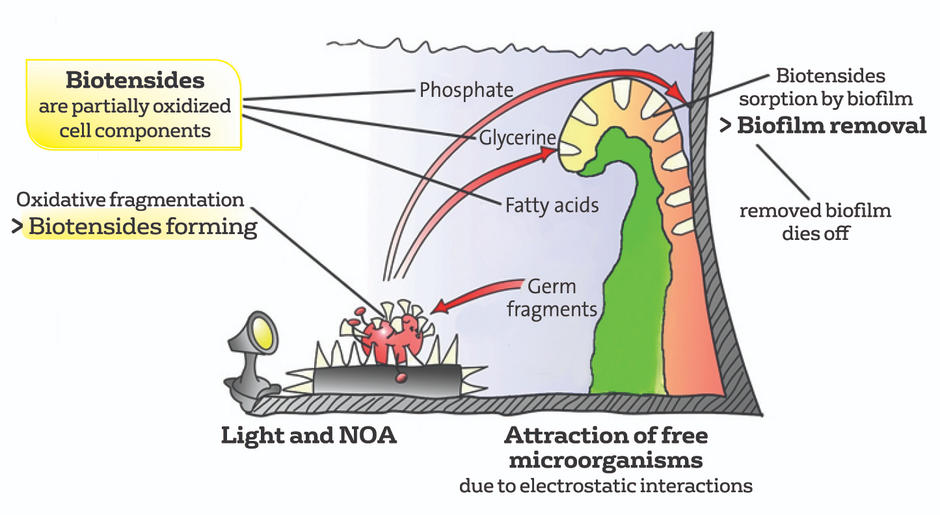

BerkeLYT high performance catalysts will attract fragments of microorganisms - such as bacteria, yeast or molds - present in the water systems by electrostatic charging. On the catalyst surface these germ fragments are degraded. Through this process so-called biosurfactants are produced. These biosurfactants will cause a removal and dying off of the biofilm present in the surface materials, as well as prevent the development, therefore will reduce the risk of Legionella.

Two core technologies are utilized:

- BerkeLYT Green

- BerkeLYT OXY